Download

Download

Search...

Search...

Download

Download

Search...

Search...In various industrial and work environments, personal protective equipment (PPE) plays a crucial role in safeguarding workers from potential hazards. Type 5 and Type 6 disposable coveralls are two essential categories of PPE designed to protect against different types of contaminants. Understanding the differences and applications of these coveralls is vital for ensuring worker safety.

Type 5 coveralls are specifically designed to protect against solid particulates such as dust, fibers, and powders. They comply with the EN ISO 13982-1 standard, which ensures they provide effective defense against airborne particles that can irritate the skin or be inhaled. These coveralls are commonly used in industries where workers are exposed to hazardous airborne solid particles, such as construction, agriculture, and certain manufacturing processes.

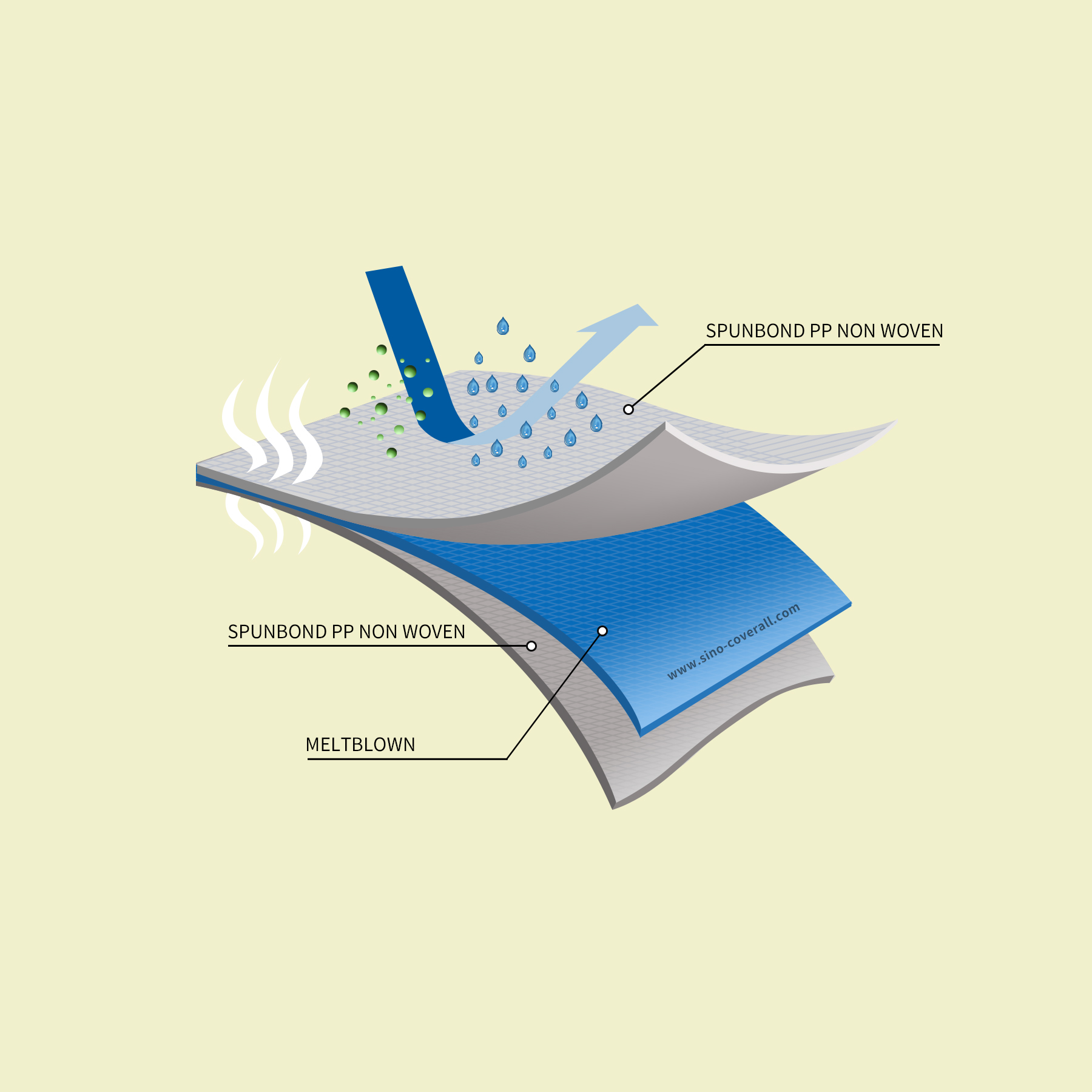

Type 5 coveralls are typically made from multi-layer SMS fabric (Spunbond-Meltblown-Spunbond), which includes a melt-blown inner filtration layer ideal for blocking tiny particulate matter. This material offers a balance between barrier protection and breathability, ensuring comfort during extended wear.

They are suitable for tasks involving insulation, wood dust, cement, fertilizers, coal, flour, and other dusty materials. For example, workers fitting fiberglass loft insulation or operating in a wood shop should use Type 5 coveralls to shield themselves from fine particles.

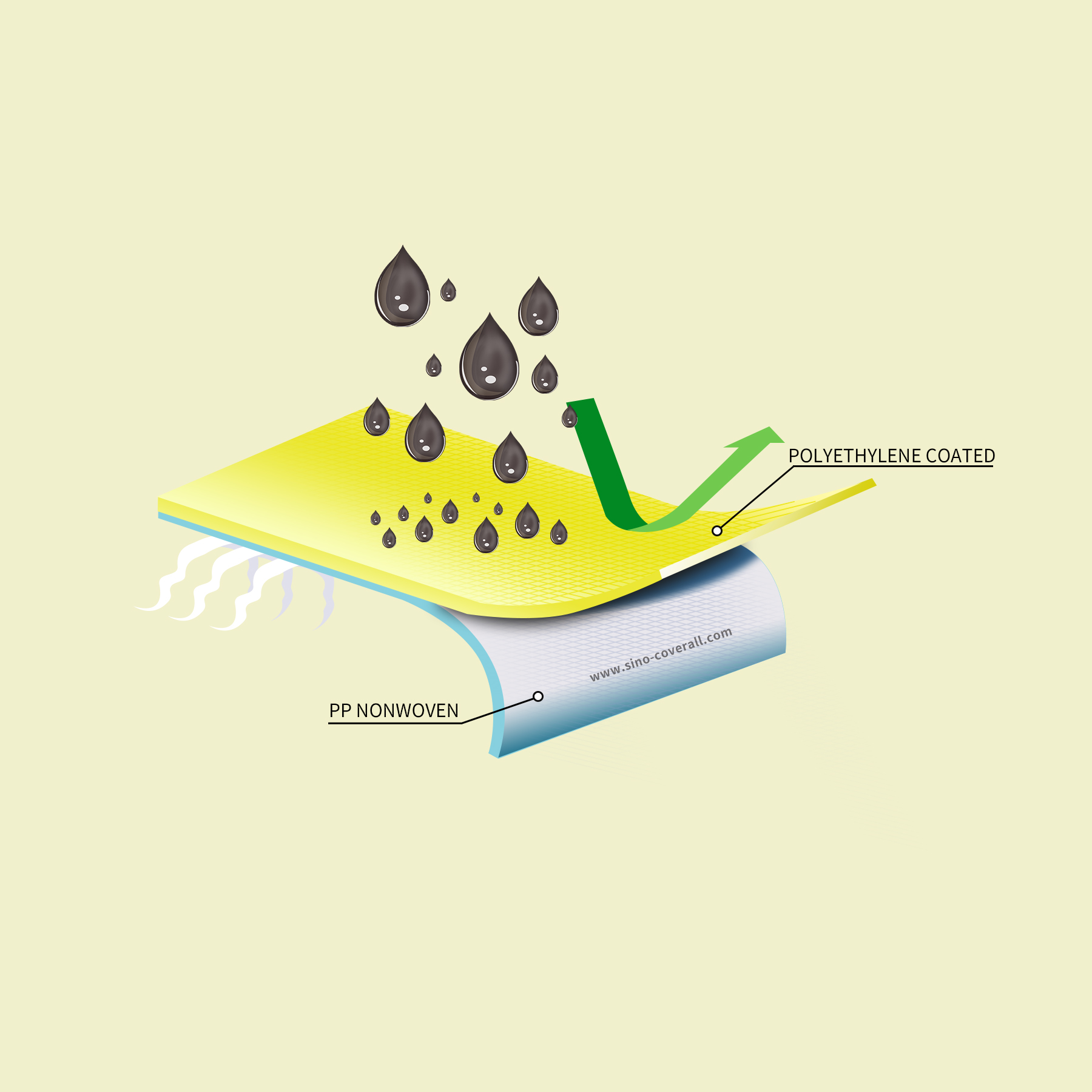

Type 6 coveralls, on the other hand, are designed to protect against liquid splashes and sprays. They meet the EN 13034 safety standard and feature a protective film laminate layer that provides a liquid barrier while remaining breathable. These coveralls are ideal for workers dealing with paint, oils, detergents, diluted acids/alkalis, and other potential wet hazards with a limited risk of soaking through the fabric.

The fabric used in Type 6 coveralls is tested with various chemicals, including sulfuric acid, sodium hydroxide, and o-xylene, to ensure its effectiveness against liquid hazards. The liquid-repellent and anti-static materials promote quick drying and prevent static build-up around flammable substances.

Type 6 coveralls are commonly used in painting, food processing, and other industries where workers are at risk of exposure to liquid splashes. They are also suitable for general industrial cleaning and maintenance tasks where liquid hazards are present.

For environments where both particulate and liquid hazards are present, Type 5/6 coveralls offer a versatile solution. These coveralls combine the protective features of both Type 5 and Type 6, providing comprehensive protection against solid particulates and light liquid splashes. They are made from materials like SMS fabric or microporous laminated fabric, which offer excellent barrier properties while maintaining breathability.

Type 5/6 coveralls often include additional protective features such as elasticated cuffs and ankles, adhesive zip flaps, and taped and bound seams to ensure a secure fit and prevent the entry of contaminants.

They are suitable for a wide range of industries, including healthcare, manufacturing, construction, and chemical sectors, where workers may be exposed to both dry particulates and liquid splashes.

When selecting Type 5 or Type 6 disposable coveralls, it is important to consider the specific hazards present in the work environment. Factors to consider include the type and size of particles for Type 5 coveralls, and the nature and volume of liquid hazards for Type 6 coveralls. Additionally, the durability, comfort, and fit of the coveralls should be taken into account to ensure that workers can perform their tasks efficiently and safely.

In conclusion, Type 5 and Type 6 disposable coveralls are essential PPE items that provide reliable protection against particulate and liquid hazards, respectively. By understanding their features and applications, employers can make informed decisions to provide their workforce with the appropriate PPE for their specific needs, ensuring the safety and well-being of their employees.